Industry: Steel Fabrication

Your steel fabrication shop is a busy place, perhaps with many crane operators over multiple shifts, making safety, simplicity of operation and reliability of paramount importance. Because there are often so many crane operators in these environments, crane systems may be subjected to improper use such as inching, reverse-

NAI considers these stresses when designing cranes for steel fab shops:

- Heavy-

duty Class D crane systems that are designed and built to make twice as many lifts per hour and lift the full rated load 30% more often than a moderate- duty Class C crane. There is virtually no limit to the lifting capacity we can design for - Reliable chain hoists, often at slower and single speeds for safety

- Simple and safe control systems

- Thermally protected motors

- Other features [???]

Industry: Maintenance Facilities

Overhead cranes -

- Elevated runways and single-

pole jibs maximize valuable floor space for productive maintenance activities - The need for only minimal training for overhead crane systems is particularly attractive for maintenance environments where cranes are used infrequently (such as periodic equipment maintenance in power, water and waste water treatment plants)

- Overhead traveling cranes can access all areas of the maintenance bay, and they can lift and move equipment effectively, regardless of floor-

level obstructions and uneven floor surfaces. In contrast, forklift- type material handling methods cannot operate effectively in these environments - Overhead crane systems can be designed to provide for precise control, high capacity, long lift or high duty cycle -

or any combination required by your particular environment - NAI heavy-

duty Class D crane systems are built to require minimal maintenance, reducing the burden on your maintenance staff

Overhead crane systems are used in a wide variety of equipment maintenance applications, including:

- Power plants

- Water and waste water treatment facilities

- Aircraft hangars

- Tractors and other agricultural equipment

- Construction and snow removal vehicles

- Railcars and other railroad equipment

- Military motor pools

- Fire apparatus

- Other fleet vehicle repair facilities

Industry: Stone Fabrication

For you, profit margins are thin, and maximizing uptime on your heavily-

NAI typically incorporates the following features in crane systems for the marble and granite industry:

- Mechanical braking systems on the trolley and bridge, which eliminate the need to adjust brakes on a regular basis (typically required every 3 months). There are no brake pads to change or adjust with our mechanical brakes, reducing overall maintenance requirements and extending the life of the wheels, gears and pinions.

- A minimum of 2 bearings per wheel. All of our bearings are heavy-

duty Class D, designed with a minimum life expectancy of 10,000 hours of actual motor on- time. This is double the life expectancy of moderate- duty Class C bearings. Our Class D bearings are also sealed- for- life and never need lubricating. - Contactors that are rated for 20,000,000 stop/start cycles when used in conjunction with electronic soft start features. These contactors should never need replacing under normal operating conditions.

- Infinitely variable speed controls which:

- Allow the operator to control precisely the movement of the hoist, trolley and end trucks, from 1% to 100% of the maximum speed

- Dramatically reduce brake wear (by 15x) by eliminating quick, repetitive starts

- Reduce wear and extend the life of gear motors and couplings

- Eliminate the need for contactors[???]

- A concrete and stone dust package that keeps the electrical controls and motors safe from the effects of airborne particles through the use of totally-

enclosed motors and gasketed control boxes. - Rail sweeps…[???]

NAI's design capabilities go far beyond this short list, however. Our engineering group custom-

Industry: Injection Molding

Are your molds single-

We also know that injection molding operations are all about control. You may have low duty cycles, but your mold-

NAI designs crane systems for the injection molding industry with these requirements in mind, typically incorporating infinitely variable speed controls. The crane systems we design and fabricate for the injection molding industry:

- Give the operator precise control over the movement of the hoist, trolley and end trucks, from 1% to 100% of the maximum speed

- Dramatically reduce brake wear (by 15x) by eliminating quick, repetitive starts

- Reduce wear and extend the life of gear motors and couplings

- Eliminate the need for contactors

NAI has supplied enough injection molding facilities to know that no two plants are alike. We have the design flexibility to respond to your unique needs as well as to the demands common to every industry-

Industry: Chemical and Metal Processing

Plating, galvanizing and dipping metal, or any other work in a highly caustic environment, requires special precautions with all your equipment, but especially with the equipment that lifts and moves materials overhead.

In many cases, a standard crane will work…for a while. Maintenance, however, will be frequent and expensive, and crane life will be short, because standard steel components rust and break down when exposed to caustic fumes and liquids. By either substituting chemical resistant materials for standard steel or applying protective coatings to the crane, the corrosive effects of the caustic agents can be minimized.

Moreover, crane equipment operating in chemical and metal processing environments operate at high duty cycles. Heavy-

NAI meets the needs of your chemical and metal processing operation with:

- Crane equipment that standardizes on heavy-

duty class D designs and components - Special components and surface finishes designed to withstand highly caustic environments

Industry: Precast Concrete

The precast industry is known for its high-

- The high volumes and significant reliance on overhead crane systems means that duty cycle are high and downtime is unacceptable. You require overhead lifting equipment that can stand up reliably to the near-

constant punishment you subject it to. - Some precast facilities generate a significant amount of concrete dust in their operations. These airborne dust particles can wreak havoc in the electrical panels, motors and many moving parts of a standard crane.

- Throughout your casting process, you may use overhead cranes to strip, flip and pour. These activities, as well as the suction that can occur as forms break free from molds, can place asymmetrical loads or loads in excess of rated capacity on the crane equipment. If your crane equipment cannot handle these activities, you’re faced with costly downtime.

- Many facilities use more than one hoist or crane system during the stripping, flipping and pouring processes, so you want to be sure they work reliably in synchronization.

NAI has been a reliable partner to the precast industry, providing durable, reliable and affordable overhead material handling systems designed to handle your challenging environment:

- Our heavy-

duty Class D crane equipment is designed and built to make twice as many lifts per hour and lift the full rated load 30% more often than a moderate- duty Class C crane. - Our concrete and stone dust package keeps electrical controls and motors safe from the effects of airborne particles through the use of totally enclosed motors, rail sweeps and gasketed control boxes.

- If you are stripping molds vertically out of forms, a hoist with true vertical lift is important. We offer both wire rope and electric chain hoists with true vertical lift.

- With multiple hoists or cranes operating so closely together, we design our systems with the appropriate limit switches and synchronization features so that both functionality and safety are accounted for.

- We accommodate your unusual duty cycle requirements by incorporating lower capacity auxiliary hoists into many precast concrete crane systems or by using a vast array of design tools to engineer custom solutions for your unique needs.

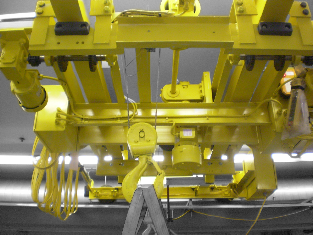

Industry: Shipbuilding

Your shipbuilding operation has had to cut costs and operate as efficiently as possible to respond to the changing needs of a global market. To you, peak efficiency means having reliable, durable equipment that doesn't hamper you with unplanned downtime or repairs. Quite often you operate at high lifting capacities, with dimensionally large and asymmetrical loads. You may need to operate the crane from above, below or the side. Your environment, whether outside or inside, might include corrosive salts and significant moisture.

Our crane systems respond to your needs with thoughtful design features to keep your shipbuilding operation efficient and competitive:

- Heavy-

duty Class D crane systems that are designed and built to make twice as many lifts per hour and lift the full rated load 30% more often than a moderate- duty Class C crane. There is virtually no limit to the lifting capacity we can design for - Versatile and easy to use controls, incorporating any combination of remote-

controlled, cab- operated, or floor- operated systems - Specialized, watertight electrical enclosure packages that are designed to withstand the outdoor elements you experience in your dry-

dock or shipyard operation - Surface finishes tested and proven in indoor or outdoor, salt-

or fresh- water environments - Crane systems with multiple hoists and trolleys to give shipyards that build smaller yachts/boats the flexibility to lift smaller components more efficiently and entire vessels when needed

- Runway options that are nearly limitless, allowing you to utilize your existing or new space as efficiently as possible

Industry: Modular Homebuilding

Shorter construction time, lower costs and better quality have all contributed to the exploding popularity of pre-

NAI crane systems for modular home construction are built with your needs in mind:

- NAI heavy-

duty Class D crane equipment is rated for significantly higher duty cycles than its moderate- duty Class C counterparts - Custom-

designed runways and girders allow an NAI crane system to conform to the dimensional constraints of your facility, maximizing productive space and giving you the flexibility your operations require - Custom-

engineered NAI crane equipment has many more options to improve safety and productivity according to the specific needs of your facility. These can include dust- proof electrical enclosures, rail sweeps and explosion- proof equipment for certain saw- cutting applications, where large accumulations of airborne wood dust are highly combustible.

Industry: Hot Metals

Your hot metal environment poses risks to crane equipment which can result in premature wear or damage. These risks include:

- Weakening metal structures

- Material splatter

- Hazardous heat blasts from pouring metal

NAI brings a deep understanding of these risks and incorporates many safety precautions into its crane system designs, including:

- Power circuit limit switch

- A 6:1 safety ratio, providing braking strength at 6x the rated capacity. The rest of the industry offers a factor of 5x.

- High-

temperature wiring and lubrication (Ask GMW) - Heat shields on the hook and hoist body made of reflective material that deflects a heat blast resulting from pouring metal or splattering material

- Audible warning devices

- Remote controls to keep workers away from dangerous loads

- Electrical panels located on the 'cool side' end truck

- When requested, NAI crane systems are designed and built to conform to Foundryman's Code specifications (Ask GMW).

Return to topReturn to topReturn to topReturn to topReturn to topReturn to topReturn to topReturn to topReturn to top

Return to topReturn to topReturn to topReturn to topReturn to topReturn to topReturn to topReturn to topReturn to top

Products |

Services |

Learning Center |

Industries |

Contact Us |

|

|

||||

|

Case Studies |

Aircraft Hangars |

|

||

|

Crane Glossary |

|

|||

|

NAI In The News |

|

|||

|

|

|

|||

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

© NAI Cranes, LLC 2008- |

|

|||